| Název: Name: | Mauser K98k | Mauser K98k |

| Originální název: Original Name: | Mauser K98k | |

| Kategorie: Category: | opakovací puška | repeating rifle |

| Výrobce: Producer: | DD.MM.1934-DD.MM.1945 Waffenfabrik Mauser AG, Oberndorf am Neckar DD.MM.1934-DD.MM.1945 J.P. Sauer & Sohn Gewehrfabrik, Suhl DD.MM.1935-DD.MM.1942 Erfurter Maschinenfabrik Berthold Geipel GmbH, Erfurt DD.MM.1935-DD.MM.1945 Waffenfabrik Mauser AG, Borsigwalde DD.MM.1936-DD.MM.1943 Berlin-Lübecker Maschinenfabrik Bernhard Berghaus, Lübeck DD.MM.1937-DD.MM.1945 Berlin-Suhler-Waffen-und Fahrzeugwerke, Suhl DD.MM.1939-DD.MM.1945 Steyr-Daimler-Puch A.G., Steyr DD.MM.1939-DD.MM.1945 Gustloff Werke, Weimar DD.MM.1942-DD.MM.1945 Waffen Werke Brünn AG,, Považská Bystrica DD.MM.1943-DD.MM.1945 Waffen Werke Brünn AG, Brno | |

| Technické údaje: Technical Data: | ||

| Hmotnost nenabité zbraně: Weight Unloaded: | 3.7–4.1 kg | 8.2–9.0 lb |

| Ráže: Calibre: | 7,92 mm | |

| Náboj: Cartridge: | 8 x 57 IS | |

| Délka: Length: | 1110 mm | 3 ft 7 ¾ in |

| Délka hlavně: Barrel Length: | 600 mm | 1 ft 11 ⅝ in |

| Kapacita zásobníku: Magazine Capacity: | 5 | |

| Výkony: Performance: | ||

| Rychlost střelby: Rate of Fire: | - ran/min | - rpm |

| Úsťová rychlost: Muzzle Velocity: | 860 m/s | 2821.5 ft/s |

| Uživatelské státy: User States: | ... | ... |

| Poznámka: Note: | nazývána také Karabiner 98 kurz, Karabiner 98k | also known as Karabiner 98 kurz, Karabiner 98k |

| Zdroje: Sources: | https://en.wikipedia.org/wiki/Karabiner_98k www.policejninoviny.cz | |

Mauser K98k

Mauser K98k

History

From the final battles of the First World War in the autumn of 1918, Germany emerged as the main defeated state and its further fate was fully in the hands of the victorious treaty powers - Great Britain, France and Italy (Russia made a separate peace with Germany on March 3, 1918 in Brest, Lithuania) - which met at a conference in Versailles, France. The result of the conference was the so-called Treaty of Versailles, which allowed Germany for its time a small, volunteer army - Reichswehr - numbering 100,000 members. The Reichswehr was also permitted by treaty only a certain type of armament (for example, the air force or the tank army was banned), which, like the entire German armaments industry, was subject to constant supervision by inspectors of the treaty powers. Over the years, however, the attention of French arms inspectors declined, fascist Italy was not interested in inspection activities, and the United Kingdom even ceased its inspectors. In this situation, German arms companies, which were otherwise in danger of bankruptcy, began working with the support of the German government on the secret development of new weapons. The mutually beneficial cooperation between Germany and the Soviet Union in the field of aviation and armored vehicles at the turn of the 1920s and 1930s is well known, but development has also taken place in the field of small arms. All activities aimed at the development of new weapons were strictly classified in Germany, but from the rise of Adolf Hitler to power in 1933 degree secrecy declined until in 1935 the establishment of a "new" German army, based on the goalie principle - of the Wehrmacht - was officially announced and plans to rearm Germany began. From that moment on, the German fascists paved the way for the gradual militarization not only of industry but also of German society as a whole, and with aggressive policies towards neighboring countries, especially Czechoslovakia and Poland, opened the door to the largest and most terrible war in human history - World War II.

The main armament of the Reichswehr since 1923 was a carbine Mauser K98b caliber 7.9 mm (8x57JS cartridge), which was based on the pre-war repeater Mauser G98. However, it was clear that the 1250 mm long weapon already completely lagged behind the requirements for an individual's basic weapon in the post-war era. As early as 1924, therefore, Mauser introduced a new type of "civilian" rifle, called the " Standard Model". The weapon was again based on the pre-war rifle G98, from which differed mainly the main, shortened to 600 mm (G98 had a barrel length of 740 mm) and from significant elements, on the contrary, kept a straight handle of the breech and the lower attachment of the belt. " However, the standard model" was only produced for export, mainly to China. The weapon bore the then common marking of Mauser's civilian weapons - the manufacturer's emblem (Mauser barrel) on the upper surface of the breech sleeve and the designation " Standard Model" and the year of manufacture on the left side of the breech case. Between 1929 and 1930, the Reichswehr conducted comparative tests of the " standard model" with the K98b carbine, but the soldiers leaned towards the original K98b, but with a shortened main and side mounting of the support belt.

Based on the results of these tests, Mauser presented in 1933 the so-called " Gewehr für Deutsche Reichspost", or "rifle for the German Reich Post." Although it was a purely military weapon, a somewhat unusual name arose due to the already described secrecy of the development of military weapons. The rifle already carried most of the elements that later characterized the K98k carbine - a barrel with a length of 600 mm, a downward bent breech, fastening the belt, visor, ..."Imperial Post" rifles were marked with the Mauser barrel emblem and the year of manufacture on the left side of the breech case. Most of these weapons were assigned to Nazi party units SA and SS. However, for reasons of secrecy, the letters "D.R." were marked on the left of the stock head. ( Deutsche Reichsbahn - German Reich Railway) or D.R.P. ( Deutsche Reichspost - German Imperial Post Office).

With such refined knowledge, the armaments office of the Reichswehr at the beginning of 1934 announced requirements for a new standard rifle of the German army. The armaments offices were Mauser and J. P. Sauer presented prototypes of practically identical weapons (only the details of the stock fittings differed), based on the "mail rifle". The rifle was officially accepted into service on June 21, 1935 under the designation " Karabiner 98 course" (carbine 98 short), abbreviation " K98k". However, about a quarter of a million rifles were made and handed over to the army before the official order to introduce into service.

The K98k rifle became the basic infantry weapon of the German Wehrmacht and from its introduction until 1945, every German soldier was trained with it and for most of them it was, for the entire period of military service. , and war, the only weapon. At the beginning of World War II, the Wehrmacht had a total of 2,769,533 K98k rifles, and a total of over 14 million were produced. The price of one K98k in 1939 was 70 Reichsmarks.

Further development

Although the first series of K98k were delivered before the official introduction into service, there was initially a shortage of new rifles. The main reason was insufficient capacity of production plants. Due to the pressure to rearm the Wehrmacht as soon as possible with a new rifle, it was therefore also necessary to modify older rifles G98 and K98b and standard K98k. These weapons are easily identifiable by the original marking on the left of the breech case.

The stock was initially made of solid walnut or beech wood, since 1937 of laminated wood. The production of the laminated stock consisted of a composition of about 1.5 mm thick beech veneers, their compression by a press and impregnation with phenolic resin (a similar technology was used in the Soviet Union to produce shell hulls and wings of many fighters during the war). The laminated stock had much higher strength and durability than solid wood, but its machining was much more difficult. A small series of K98k rifles was experimentally fitted into a plastic stock. Tests have shown that the selected plastic has satisfactory mechanical properties, but these weapons were not mass-produced, mainly because in cold weather the selected plastic behaved like metal and fingers froze to it without gloves. To date, only four specimens of the K98k rifle with a plastic stock have survived (one of which is owned by the ACR Military History Institute).

From the beginning of 1943, the design of weapons (not only K98k) was simplified with regard to the lowest possible costs and the highest possible mass production. Initially, the individual parts of the K98k rifle were manufactured by milling, the surface of the parts was ground and then blackened. However, machining is a financially and time-consuming technology, so many components have been gradually redesigned so that much cheaper and more productive pressing can be used to produce them.

Furthermore, the shape of some components has been changed (understandably simplified) in order to reduce the number of production operations. On the K98k rifle, the shape of the blow holes in the breech was gradually changed from oval to circular, the guide rib of the breech was omitted and the disc for disassembly of the breech replaced the simple hole in the stock shoe ...

Another direction of streamlining the production of weapons was the reduction of production operations, the omission or simplification of which did not affect the functionality of the weapon. During the war, only the functional surfaces of individual components were machined more and more precisely.

In a simplified way, design and technological modifications can be divided into individual years.In 1938, the walnut wood of the stock was replaced by beech veneer (see above). In 1939, a tunnel cover was introduced (it was made of coiled spring sheet, which fitted into the grooves in the fly carrier - it was not simplification, rather the opposite) and the metal muzzle cover was replaced by rubber (but it had undeniable advantages, because it was not must be removed before firing and it was possible to pierce it; four weapons were supplied with each weapon). In 1940, the first part of the machined part was replaced by a pressed part - the stock shoe, which also got higher walls, enclosing the stock head (the shoe actually formed a kind of cup), which prevented the splitting of the laminated stock. There was no change in the design of the K98k in 1941, but since 1942 a wave of simplification of the weapon has begun - the shape of the upper barrel sleeve is simplified (it no longer has the typical shape of the letter H, but is still produced by milling) and caliber calibration was simplified. Another simplification was introduced in 1943 - the upper barrel sleeve begins to be made by welding of pressed sheet metal, the trigger guard and the bottom of the ammunition box begin to be pressed.

Much more penetrating simplifications took place in 1944 - instead of blackening the parts, phosphating began to be used (phosphate color varies according to the current composition of the bath at individual suppliers), final fine machining operations on non-functional surfaces are omitted (surface bears clear traces of machining), more and more parts are produced by pressing (lower main sleeve, cartridge feeder, ...) the locking screws of the bottom of the cartridge box are no longer used, the visor is simplified, now calibrated in the range of only 100 to 400 meters, and mainly K98k is produced from good parts of scrap barrels for machine gun MG 34.

At the end of 1944, the need for simplification became so much that it was decided to produce a war model rifle (Kriegsmodell K98k/a), which is a roughly processed and very simplified variant of the K98k. For example, the bayonet catch was completely omitted, the wiper was released, the simple sight was firmly soldered to the barrel (in front of the ammunition chamber), the pressed barrel sleeves were attached to the stock with screws, the breech disassembly bed was missing and the guide rib was omitted from the breech. In addition, at the end of the war came to the units and weapons without any surface treatment of the stock.

In general, after 1942, the quality of all German weapons was variable due to fluctuating material quality, disruption of production by Allied bombing, lack of raw materials, shortage of skilled workers and, last but not least, "lack of work discipline" of foreign workers in the occupied countries or totally deployed in Germany, or prisoners from concentration camps.

After the war

A large number of K98k rifles remained in service after World War II, only changing owners. Post-war users were Czechoslovakia, China, Denmark, France, Israel, Yugoslavia, GDR, Norway and Germany.

The last paragraph of the article deals with the K98k service in Czechoslovakia.

Weapons purchased by China were included in the army, and some of them reached the battlefield of the Korean Peninsula in the early 1950s.

The Danish K98k were included in the militia armament, but before that they underwent overhaul in the armory Schultz & Larsen in Otterup, where the weapons received new barrels, chambered for ammunition 6,5x55SE and logically also new visors. Due to the greater wall thickness of the new barrel, the total weight of the weapon modified in this way was about half a kilogram higher than the standard K98k with a laminated stock.

The Israeli K98k, purchased mostly in Czechoslovakia, did an excellent job in 1956 during the so-called Sinai War. At the turn of the 50s and 60s, they were pierced for ammunition 7,62x51 NATO and a small number of them served in the Israeli militia in 80s.

Norwegian K98k were, after the introduction of the American self-loading rifles M1 Garand as standard weapons, in the Royal Armory in Kongsberg reloaded with ammunition 30-06 Springfield and also handed over to the Norwegian militia.

In the Federal Republic of Germany, K98k rifles were used for a short time by border police units. These weapons came from post-war production at the Mauser plant in Oberndorf.

K98k variants

In 1941, a sniper rifle was derived from the basic K98k model. It was characterized by the installation of an optical telescopic sight ZF41 (abbreviation ZF means Zielenfernrohr) with 1.5x magnification. An interesting feature that distinguished this model from other snipers was the mounting of the optics on the dovetail, mounted on the left side of the base of the visor. This allowed for low mounting of the optics, which, moreover, did not interfere with charging from the tapes; however, the disadvantage was the small viewing angle of the optics.

A smaller number of K98k snipers were equipped with an optical telescopic sight ZF4 with 4x magnification, which was originally designed for a sniper version of a self-loading rifle G43 . The ZF4 sight mount was attached to the left side of the breech housing. Due to the optics, the shape of the fuse wing had to be changed so that it could be moved under the optics tube.

According to some sources, a telescopic sight ZF42 with 5 times magnification was also mounted on the K98k.

The second variant of the K98k was a rifle with a grenade launcher, introduced in 1942. At the muzzle of such a weapon was mounted a device for firing rifle grenades. In each infantry team of the Wehrmacht there was one soldier equipped with a rifle with a grenade launcher and a supply of appropriate ammunition.

The grenade launcher has a caliber of 30 mm, the guide part of the bore is provided with eight grooves and its total weight is 0.78 kg. The grenade launcher could fire various types of fragmentation and anti-tank (cumulative) grenades up to a distance of 250 meters.

Special sights, mounted on the left side of the weapon under the ammunition chamber, were used to aim the grenade launcher.

Construction

The Mauser K98k rifle is a repeating weapon with a revolving retractable breech. The ammunition is stored in a two-row, fixed ammunition box, situated in front of the trigger guard. The box is filled from above using a charging tape.

The main parts of the rifle are: Barrel with sights, breech case, breech, ammunition box and stock.

The barrel with a length of 600 mm is equipped with four clockwise grooves, with a constant pitch of 240 mm. The rear part of the bore mainly passes into the charge chamber.

The base of the visor is soldered on the back of the barrel; in the front part of the barrel is soldered to the base of the fly. The barrel has a thread in the rear part, which is screwed into the breech case.

The breech case connects all the basic parts of the weapon into one unit. In the front part of the breech housing, in the sleeve of the housing, there is a thread into which the barrel is screwed; in the remaining length of the housing there is a bore in which the bolt moves. Longitudinal grooves are milled in the side walls of the bore, which guide the locking teeth and thus the closure during the longitudinal movement of the closure. The rear part of the closure housing is closed from above and forms a so-called housing bridge; in the front part of the bridge, cutouts are milled for attaching the charging tape.

On the left side of the rear part of the bolt housing, a spring-loaded bolt holder is attached with a screw. The protrusion of the bolt holder engages in a side groove in the housing, thus forming the rear stop of the bolt and at the same time preventing it from being unintentionally pulled out.

The closure consists of a bolt, extractor, extractor ring, firing pin, drum spring, firing pin nut, closures, pin spring closures and fuses.

Three locking teeth (two at the front and one at the rear) are milled in the bolt, which fit into the respective recesses in the bolt housing; the downwardly curved handle of the breech also extends from the breech.On the right side of the bolt is a rotary extractor.

A drum spring is threaded on the firing pin and a firing pin nut is fitted to its rear end with a bayonet connection.

The firing pin nut has a bar at the bottom, the front end of which is chamfered. This chamfer corresponds in its angle to the helical surface in the notch of the bolt; when the bolt is turned to the left, the firing pin nut is pushed backwards and thus the drum spring is tensioned. At the bottom of the firing pin nut bar, there are two teeth that are used to catch the trigger lever tooth.

The closure, which is screwed to the bolt, connects the individual parts of the bolt. A fuse and a spring-loaded closure pin are housed in the cap. The pin ensures the correct position of the closure relative to the bolt and also prevents rotation of the unlocked bolt.

The aileron safety device is placed in the closure with its pin and has three positions - unlocked on the left, locked upwards and in the position of the safety wing aileron on the right it is secured and in addition blocked the movement of the closure.

A trigger device is also located in the closure housing, which consists of a trigger with a pin, a trigger spring and a trigger lever with a pin. The spring pushes the trigger lever up, where it catches the firing pin nut with its tooth. Pressing the trigger lowers the rear of the trigger lever, the tooth disengages, and the firing pin nut is released. When the trigger pressure is released, the trigger lever returns to its original position.

The cartridge box is bolted to the breech housing with two screws from below. The box is formed by the body of the box, which forms one unit with the trigger guard, bottom, feed spring and feeder. The bottom of the box is attached to the body with a spring pin. A folded flat spring is inserted in the bottom of the box, which pushes the cartridge feeder upwards. The cartridges are stored in the box in a checkerboard pattern in two rows.

The stock and forearm are made of solid walnut wood or, more often, of laminated beech veneer; exceptionally, the stock was made of another type of solid wood. The breech case is attached to the stock by means of two through screws, which at the same time connect the case with the cartridge case. In front of the breech case, a barrel is placed in the stock along its entire length, which barrel is attached to the stock by means of two barrel sleeves; a bayonet catch protrudes forward from the front main sleeve. The recoil of the shot is transmitted to the stock by means of a square pin bed located under the ammunition chamber.

In the head of the stock there is an opening for threading the carrying belt and behind it there is a bed for disassembling the breech. The rear part of the stock head is protected against damage by a steel shoe.

Technical data

Caliber - 7.9 mm

Hub - 7,9 mm mod. 98 (today's designation 8x57JS)

Length - 1110 mm

Length with bayonet - 1340 mm

Length with grenade launcher - 1265 mm

Empty weight - with walnut stock - 3.7 kg

Empty weight - with beech stock - 3.9 kg

Empty weight - with laminated stock - 4.1 to 4.2 kg

Empty weight - with plastic stock - 4.06 kg

Weight of loaded weapon with bayonet - 4.33 kg (with walnut stock)

Weight with grenade launcher and sight - 5.35 kg (with walnut stock)

Barrel length - 600 mm

Number of grooves in the barrel - 4

Bore pitch - 240 mm

Sense of ascent - true

Depth of grooves - 0.12 mm

Groove width - 4.40 mm

Muzzle velocity - 860 m/s

Ammunition box capacity - 5 rounds

Visor range - 100 to 2000 m

Handling K98k rifle:

Hold the weapon under the ammunition box with your left hand. Grasp the handle of the breech with your right hand, turn it to the left upwards and pull the breech back. On the right, grab the charging strap with the hubs and insert it into the cutout in the bridge of the breech case. Then we support the bottom of the cartridge case from below with four fingers of the right hand, place the thumb on the highest cartridge and push the cartridges into the box with the pressure of the thumb. With the right hand, grasp the handle of the breech, move the breech forward, thus inserting the highest charge into the chamber. After reaching the end to the front position and turn the crank to the right. The charging strap falls off when the shutter moves forward.

After the shot, we reload the weapon by turning the handle to the left up, pulling the breech back to the stop, which pulls it out of the chamber and throws the empty cartridge case. Then move the bolt forward as far as it will go and lock it by turning the handle to the right. The weapon is ready for another shot.

Production

In total, about 14 million K98k rifles were produced. The last series of K98k rifles was produced in Germany between August 1945 and June 1946 for the needs of the French army. The production of K98k for the needs of the Czechoslovak Army after the war also took place in the Brno Armory.

Production in individual plants:

Races in Germany:

5,154,000 pcs - Mauser-Werke A.G., Oberndorf am Neckar

1,089,000 pcs - Mauser-Werke A.G., Berlin-Borsigwalde

1 981 000 pcs - J. P. Sauer -und Sohn Gewehrfabrik, Suhl

654,000 pcs - Erfurter Maschinenfabrik Berthold Geipel GmbH (ERMA), Erfurt

878 000 pcs - Berlin-Lübecker Maschinenfabrik Bernhard Berghaus, Lübeck

131,000 pcs - Berlin-Suhler-Waffen-u. Fahrzeugwerke, Suhl

1,216,000 pcs - Gustloff Werke, Weimar

Plants in occupied countries:

965,000 pcs - Steyr-Daimler-Puch A.G., Steyr

1,030,000 pcs - Waffenwerke Brünn A.G. (Zbrojovka Brno a.s.), Brno plant

942,000 pcs - Waffenwerke Brünn A.G., plant Povážská Bystrica

Marking

The designation of the K98k rifles consisted of several elements: type designation, serial number, manufacturer's designation, year of manufacture, test marks and acceptance marks.

The type designation was located on the left side of the breech housing and had the form " Mod. 98" (without the suffix "k"). Before 1936, however, only weapons made at Mauser's parent plant in Oberndorf were marked in this way. This marking was made in ordinary block letters, for weapons manufactured by Sauer and Erma then Schwabach.

Some K98k rifles, modified from the original G98, bore the original designation " Gew. 98 ". Most of these weapons were used by the Nazi party organization SS.

The serial number was located on the left side of the breech case sleeve, on the underside of the breech handle, and on the barrel. The serial number initially consisted of three digits, later four digits and a one-letter suffix. On some parts, the serial number was repeated in abbreviated form.

The manufacturer's code first consisted of a capital letter "S" followed by a slash followed by a two- to three-digit number identifying the manufacturer - for example, Mauser-Werke in Oberndorf had the code "S/42".

In 1938, the letter "S" with a slash was deleted from the code and the manufacturer was identified only by the numerical code, which remained.

In 1940, a completely new manufacturer's code system was introduced, consisting of two to three lower case letters - for example, Mauser-Werke in Oberndorf had the code "byf".

Exceptions to this marking system were the products of Berlin-Suhler-Waffen- und Fahrzeugwerke from Suhl, which were marked with the stylized letters " BSW ", or the abbreviation of the company name.

The year of manufacture designation has also changed over time. The first two years of production were K98k rifles marked with a one-letter code - weapons made in 1934 bore the code "K", in 1935 the code "G". The code of the year followed immediately after the manufacturer's designation, but sometimes it was separated from it by a slash, exceptionally by a period. The letter was usually in capital letters, but sometimes in small print. Example: a rifle made by Mauser-Werke in Oberndorf in 1934 was marked " S/42K", a rifle made by JP Sauer in Suhl in 1935 it bore the designation " S/147/G", the weapon made in Erfurter Maschinenfabrik in 1935 was marked " S/27.g ".

Since 1936, the year of manufacture of the weapon was marked with an integer year, which was located in the rear of the upper surface of the sleeve of the breech.

From the end of 1940, the year of production was marked only by stating the last two digits of the year of production.In 1940, however, only weapons made in Steyr, Austria were marked in this way, other manufacturers did not switch to this method until the beginning of 1941. An exception to this system were weapons made by the Brno Armory, which was now called Waffenwerke Brünn. A.-G.[/I] Her weapons were marked until the end of 1944 for the whole year of production.

In addition to the manufacturer's name, there was also a military acceptance mark on the right of the breech case. In each production plant, there was a group of officers of the Waffenamt (armaments office), which was responsible for taking over weapons for the army. The commanding officer of each group was assigned a set of verification mark stamps ( Abnehmestempel) with an assigned number. There were more stamps, of course, but all members of the group used the same number. After the acceptance inspection, it was marked on the weapon with the embossing of an eagle and the assigned group number, which was sometimes preceded by the abbreviation " WaA". Interestingly, the group number was not tied to the production plant, but to the person of the group's commanding officer - if he was transferred to another plant, the numbers traveled with him. The commander, coming to the vacated position, brought his own number with him, although the group had not changed otherwise.

Very often it is possible to find on the individual components of K98k rifles (and other weapons) several codes of manufacturers or groups of the Waffenamt, different from the markings on the sleeve of the breech. These components were manufactured by various subcontractors and were only assembled by the final weapon supplier.

Manufacturer code K98k:

Until 1938:

BSW - Berlin-Suhler-Waffen-u. Fahrzeugwerke, Suhl

S/27 - Erfurter Maschinenfabrik GmbH, Erfurt

S/42 - Mauser-Werke A.G., Oberndorf

S/147 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl

S/237 - Berlin-Lübecker Maschinenfabrik, Lübeck

S/243 - Mauser-Werke A.G., Berlin-Borsigwalde

From 1938 to 1940:

BSW - Berlin-Suhler-Waffen-u. Fahrzeugwerke, Suhl

27 - Erfurter Maschinenfabrik GmbH, Erfurt

42 - Mauser-Werke A.G., Oberndorf

47 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl

147 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl

237 - Berlin-Lübecker Maschinenfabrik, Lübeck

243 - Mauser-Werke A.G., Berlin-Borsigwalde

337 - Berlin-Suhler-Waffen-u. Fahrzeugwerke, Suhl

660 - Steyr-Daimler-Puch A.G., Steyr

In the years 1940 - 1945:

ar - Mauser-Werke A.G., Berlin-Borsigwalde

ax - Erfurter Maschinenfabrik GmbH, Erfurt

ayf - Erfurter Maschinenfabrik GmbH, Erfurt

bcd - Gustloff Werke, Weimar

bnz - Steyr-Daimler-Puch A.G., Steyr

byf - Mauser-Werke A.G., Oberndorf

ce - J. P. Sauer -und Sohn Gewehrfabrik, Suhl

dot - Waffenwerke Brünn A.G. (Zbrojovka Brno a.s.), Brno plant

dou - Waffenwerke Brünn A.G. (Zbrojovka Brno a.s.), Povážská Bystrica plant

duv - Berlin-Lübecker Maschinenfabrik, Lübeck

swp - Waffenwerke Brünn A.G., Brno plant (only in 1945)

svw - Mauser-Werke A.G., Oberndorf (only in 1945)

svw MB - Mauser-Werke A.G., Oberndorf (weapons made in 1945 for the occupation administration)

Waffenamt acceptance marks:

1 - Gustloff-Werke, Weimar (1940-1941 and 1944-1945)

2 - Mauser Werke A.G., Oberndorf

4 - Berlin-Suhler-Waffen-u. Fahrzeugwerke, Suhl (1937-1939)

26 - Berlin-Lübecker Maschinenfabrik, Lübeck (1936-1938)

26 - Gustloff-Werke, Weimar (1942-1943)

26 - Mauser Werke A.G., Berlin-Borsigwalde (1939-1944)

42 - Mauser Werke A.G., Oberndorf

46 - Berlin-Suhler-Waffen-u. Vehicle works, Suhl (1939)

63 - Mauser Werke A.G., Oberndorf (1936-1939)

63 - Waffenwerke Brünn A.G., Brno plant (1943-1944)

63 - Waffenwerke Brünn A.G., plant Povážská Bystrica (1945)

74 - Mauser Werke A.G., Oberndorf (1934)

77 - Erfurter Maschinenfabrik GmbH, Erfurt (1937-1938)

77 - Steyr-Daimler-Puch A.G., Steyr (1942-1944)

80 - Waffenwerke Brünn A.G., Brno plant (1942)

80 - Waffenwerke Brünn A.G., plant Povážská Bystrica (1943-1945)

91 - Mauser Werke A.G., Oberndorf (1934)

114 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl (1934-1935)

116 - J. P.Sauer -und Sohn Gewehrfabrik, Suhl (1934-1936)

132 - Erfurter Maschinenfabrik GmbH, Erfurt (1935)

135 - Mauser Werke A.G., Oberndorf (1942-1945)

149 - Berlin-Lübecker Maschinenfabrik, Lübeck (1938)

165 - Mauser Werke A.G., Oberndorf (1935)

167 - Mauser Werke A.G., Oberndorf (1935)

211 - Mauser Werke A.G., Berlin-Borsigwalde (1935-1936)

214 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl (1936-1940)

214 - Berlin-Lübecker Maschinenfabrik, Lübeck (1941-1941)

280 - Erfurter Maschinenfabrik GmbH, Erfurt (1936-1940)

280 - Mauser Werke A.G., Berlin-Borsigwalde (1937-1938)

280 - Berlin-Lübecker Maschinenfabrik, Lübeck (1938)

280 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl (1942-1944)

280 - Erfurter Maschinenfabrik GmbH, Erfurt (1940-1941)

359 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl (1936-1943)

359 - Erfurter Maschinenfabrik GmbH, Erfurt (1941)

411 - Erfurter Maschinenfabrik GmbH, Erfurt (1936)

613 - Mauser Werke A.G., Berlin-Borsigwalde (1941)

623 - Steyr-Daimler-Puch A.G., Steyr (1939-1945)

655 - Mauser Werke A.G., Oberndorf (1939-1941)

K98k in Czechoslovakia

The first K98k rifles appeared on the territory of the former Czechoslovakia in the second half of the 1930s under well-known tragic circumstances - they found themselves in the hands of terrorists from the Sudeten German paramilitary organization Freikorps. Members of the Freikorps, willingly supplied and ideologically incited by Hitler's Germany, led a terrorist campaign on the Czech border, and the main targets of their insidious attacks were mainly symbols of Czechoslovak statehood - soldiers, gendarmes, members of the Financial Guard and civil servants.

The second wave of K98k rifles "came" to our territory in even more tragic circumstances - along with the occupying forces of the Wehrmacht in March 1939, which settled in our country for the next six years.

During the war in the German Wehrmacht, the need (and consumption) of all kinds of weapons constantly increased. At the beginning of 1942, the production of K98k rifles was terminated at the Erfurt plant Erma, which fully switched to the production of a submachine gun MP-40, and it was necessary to quickly find new production capacity. These were found in the former subsidiary of Brno's Zbrojovka in Povážská Bystrica, Slovakia, which had experience from the pre-war period with the production of Czechoslovak army rifles vz.24. The adoption of production took place relatively quickly, and in 1942 95,000 K98k rifles were produced. A total of 942 thousand of these weapons were produced in Povážská Bystrica.

In 1943, the production of K98k rifles began in the main Brno plant Zbrojovka, as a replacement for the termination of production in the Berlin-Lübecker Maschinenfabrik, which has since focused on the production of self-loading rifles G43. In the first year of production, 1943, 220,000 K98k rifles left the Brno plant and a total of 1.03 million weapons by the end of the war.

After the Second World War, an extensive "legacy" of the German occupiers remained in our territory, which also included a considerable number of K98k rifles. Due to the lack of other weapons and the need for uniform armament of the renewed army, K98k rifles were included in the armament of the Czechoslovak Army under the designation vz.98N. Other German weapons classified in this way were, for example, assault rifles StG44, machine guns MG34 or pistole P38. In addition, an undetected number of prey rifles were delivered from the Soviet Union. These weapons were called "Stalingrad rifles" in our army because they were allegedly captured during the Battle of Stalingrad.

What is more important, the production of rifles vz.98N for Czechoslovakia. the army in Brno's Zbrojovka took place for several years after the end of the war. In the Czechoslovak armament. army rifles vz.98N lasted until the early 50s, when they were gradually replaced submachine guns vz.23/24/25/26 a samonabíjecími puškami vz.52.

Part of the loot weapons was sold to Israel in 1948, the remaining vz.98N were sold abroad after being expelled from the army.

History

From the final battles of the First World War in the autumn of 1918, Germany emerged as the main defeated state and its further fate was fully in the hands of the victorious treaty powers - Great Britain, France and Italy (Russia made a separate peace with Germany on March 3, 1918 in Brest, Lithuania) - which met at a conference in Versailles, France. The result of the conference was the so-called Treaty of Versailles, which allowed Germany for its time a small, volunteer army - Reichswehr - numbering 100,000 members. The Reichswehr was also permitted by treaty only a certain type of armament (for example, the air force or the tank army was banned), which, like the entire German armaments industry, was subject to constant supervision by inspectors of the treaty powers. Over the years, however, the attention of French arms inspectors declined, fascist Italy was not interested in inspection activities, and the United Kingdom even ceased its inspectors. In this situation, German arms companies, which were otherwise in danger of bankruptcy, began working with the support of the German government on the secret development of new weapons. The mutually beneficial cooperation between Germany and the Soviet Union in the field of aviation and armored vehicles at the turn of the 1920s and 1930s is well known, but development has also taken place in the field of small arms. All activities aimed at the development of new weapons were strictly classified in Germany, but from the rise of Adolf Hitler to power in 1933 degree secrecy declined until in 1935 the establishment of a "new" German army, based on the goalie principle - of the Wehrmacht - was officially announced and plans to rearm Germany began. From that moment on, the German fascists paved the way for the gradual militarization not only of industry but also of German society as a whole, and with aggressive policies towards neighboring countries, especially Czechoslovakia and Poland, opened the door to the largest and most terrible war in human history - World War II.

The main armament of the Reichswehr since 1923 was a carbine Mauser K98b caliber 7.9 mm (8x57JS cartridge), which was based on the pre-war repeater Mauser G98. However, it was clear that the 1250 mm long weapon already completely lagged behind the requirements for an individual's basic weapon in the post-war era. As early as 1924, therefore, Mauser introduced a new type of "civilian" rifle, called the " Standard Model". The weapon was again based on the pre-war rifle G98, from which differed mainly the main, shortened to 600 mm (G98 had a barrel length of 740 mm) and from significant elements, on the contrary, kept a straight handle of the breech and the lower attachment of the belt. " However, the standard model" was only produced for export, mainly to China. The weapon bore the then common marking of Mauser's civilian weapons - the manufacturer's emblem (Mauser barrel) on the upper surface of the breech sleeve and the designation " Standard Model" and the year of manufacture on the left side of the breech case. Between 1929 and 1930, the Reichswehr conducted comparative tests of the " standard model" with the K98b carbine, but the soldiers leaned towards the original K98b, but with a shortened main and side mounting of the support belt.

Based on the results of these tests, Mauser presented in 1933 the so-called " Gewehr für Deutsche Reichspost", or "rifle for the German Reich Post." Although it was a purely military weapon, a somewhat unusual name arose due to the already described secrecy of the development of military weapons. The rifle already carried most of the elements that later characterized the K98k carbine - a barrel with a length of 600 mm, a downward bent breech, fastening the belt, visor, ..."Imperial Post" rifles were marked with the Mauser barrel emblem and the year of manufacture on the left side of the breech case. Most of these weapons were assigned to Nazi party units SA and SS. However, for reasons of secrecy, the letters "D.R." were marked on the left of the stock head. ( Deutsche Reichsbahn - German Reich Railway) or D.R.P. ( Deutsche Reichspost - German Imperial Post Office).

With such refined knowledge, the armaments office of the Reichswehr at the beginning of 1934 announced requirements for a new standard rifle of the German army. The armaments offices were Mauser and J. P. Sauer presented prototypes of practically identical weapons (only the details of the stock fittings differed), based on the "mail rifle". The rifle was officially accepted into service on June 21, 1935 under the designation " Karabiner 98 course" (carbine 98 short), abbreviation " K98k". However, about a quarter of a million rifles were made and handed over to the army before the official order to introduce into service.

The K98k rifle became the basic infantry weapon of the German Wehrmacht and from its introduction until 1945, every German soldier was trained with it and for most of them it was, for the entire period of military service. , and war, the only weapon. At the beginning of World War II, the Wehrmacht had a total of 2,769,533 K98k rifles, and a total of over 14 million were produced. The price of one K98k in 1939 was 70 Reichsmarks.

Further development

Although the first series of K98k were delivered before the official introduction into service, there was initially a shortage of new rifles. The main reason was insufficient capacity of production plants. Due to the pressure to rearm the Wehrmacht as soon as possible with a new rifle, it was therefore also necessary to modify older rifles G98 and K98b and standard K98k. These weapons are easily identifiable by the original marking on the left of the breech case.

The stock was initially made of solid walnut or beech wood, since 1937 of laminated wood. The production of the laminated stock consisted of a composition of about 1.5 mm thick beech veneers, their compression by a press and impregnation with phenolic resin (a similar technology was used in the Soviet Union to produce shell hulls and wings of many fighters during the war). The laminated stock had much higher strength and durability than solid wood, but its machining was much more difficult. A small series of K98k rifles was experimentally fitted into a plastic stock. Tests have shown that the selected plastic has satisfactory mechanical properties, but these weapons were not mass-produced, mainly because in cold weather the selected plastic behaved like metal and fingers froze to it without gloves. To date, only four specimens of the K98k rifle with a plastic stock have survived (one of which is owned by the ACR Military History Institute).

From the beginning of 1943, the design of weapons (not only K98k) was simplified with regard to the lowest possible costs and the highest possible mass production. Initially, the individual parts of the K98k rifle were manufactured by milling, the surface of the parts was ground and then blackened. However, machining is a financially and time-consuming technology, so many components have been gradually redesigned so that much cheaper and more productive pressing can be used to produce them.

Furthermore, the shape of some components has been changed (understandably simplified) in order to reduce the number of production operations. On the K98k rifle, the shape of the blow holes in the breech was gradually changed from oval to circular, the guide rib of the breech was omitted and the disc for disassembly of the breech replaced the simple hole in the stock shoe ...

Another direction of streamlining the production of weapons was the reduction of production operations, the omission or simplification of which did not affect the functionality of the weapon. During the war, only the functional surfaces of individual components were machined more and more precisely.

In a simplified way, design and technological modifications can be divided into individual years.In 1938, the walnut wood of the stock was replaced by beech veneer (see above). In 1939, a tunnel cover was introduced (it was made of coiled spring sheet, which fitted into the grooves in the fly carrier - it was not simplification, rather the opposite) and the metal muzzle cover was replaced by rubber (but it had undeniable advantages, because it was not must be removed before firing and it was possible to pierce it; four weapons were supplied with each weapon). In 1940, the first part of the machined part was replaced by a pressed part - the stock shoe, which also got higher walls, enclosing the stock head (the shoe actually formed a kind of cup), which prevented the splitting of the laminated stock. There was no change in the design of the K98k in 1941, but since 1942 a wave of simplification of the weapon has begun - the shape of the upper barrel sleeve is simplified (it no longer has the typical shape of the letter H, but is still produced by milling) and caliber calibration was simplified. Another simplification was introduced in 1943 - the upper barrel sleeve begins to be made by welding of pressed sheet metal, the trigger guard and the bottom of the ammunition box begin to be pressed.

Much more penetrating simplifications took place in 1944 - instead of blackening the parts, phosphating began to be used (phosphate color varies according to the current composition of the bath at individual suppliers), final fine machining operations on non-functional surfaces are omitted (surface bears clear traces of machining), more and more parts are produced by pressing (lower main sleeve, cartridge feeder, ...) the locking screws of the bottom of the cartridge box are no longer used, the visor is simplified, now calibrated in the range of only 100 to 400 meters, and mainly K98k is produced from good parts of scrap barrels for machine gun MG 34.

At the end of 1944, the need for simplification became so much that it was decided to produce a war model rifle (Kriegsmodell K98k/a), which is a roughly processed and very simplified variant of the K98k. For example, the bayonet catch was completely omitted, the wiper was released, the simple sight was firmly soldered to the barrel (in front of the ammunition chamber), the pressed barrel sleeves were attached to the stock with screws, the breech disassembly bed was missing and the guide rib was omitted from the breech. In addition, at the end of the war came to the units and weapons without any surface treatment of the stock.

In general, after 1942, the quality of all German weapons was variable due to fluctuating material quality, disruption of production by Allied bombing, lack of raw materials, shortage of skilled workers and, last but not least, "lack of work discipline" of foreign workers in the occupied countries or totally deployed in Germany, or prisoners from concentration camps.

After the war

A large number of K98k rifles remained in service after World War II, only changing owners. Post-war users were Czechoslovakia, China, Denmark, France, Israel, Yugoslavia, GDR, Norway and Germany.

The last paragraph of the article deals with the K98k service in Czechoslovakia.

Weapons purchased by China were included in the army, and some of them reached the battlefield of the Korean Peninsula in the early 1950s.

The Danish K98k were included in the militia armament, but before that they underwent overhaul in the armory Schultz & Larsen in Otterup, where the weapons received new barrels, chambered for ammunition 6,5x55SE and logically also new visors. Due to the greater wall thickness of the new barrel, the total weight of the weapon modified in this way was about half a kilogram higher than the standard K98k with a laminated stock.

The Israeli K98k, purchased mostly in Czechoslovakia, did an excellent job in 1956 during the so-called Sinai War. At the turn of the 50s and 60s, they were pierced for ammunition 7,62x51 NATO and a small number of them served in the Israeli militia in 80s.

Norwegian K98k were, after the introduction of the American self-loading rifles M1 Garand as standard weapons, in the Royal Armory in Kongsberg reloaded with ammunition 30-06 Springfield and also handed over to the Norwegian militia.

In the Federal Republic of Germany, K98k rifles were used for a short time by border police units. These weapons came from post-war production at the Mauser plant in Oberndorf.

K98k variants

In 1941, a sniper rifle was derived from the basic K98k model. It was characterized by the installation of an optical telescopic sight ZF41 (abbreviation ZF means Zielenfernrohr) with 1.5x magnification. An interesting feature that distinguished this model from other snipers was the mounting of the optics on the dovetail, mounted on the left side of the base of the visor. This allowed for low mounting of the optics, which, moreover, did not interfere with charging from the tapes; however, the disadvantage was the small viewing angle of the optics.

A smaller number of K98k snipers were equipped with an optical telescopic sight ZF4 with 4x magnification, which was originally designed for a sniper version of a self-loading rifle G43 . The ZF4 sight mount was attached to the left side of the breech housing. Due to the optics, the shape of the fuse wing had to be changed so that it could be moved under the optics tube.

According to some sources, a telescopic sight ZF42 with 5 times magnification was also mounted on the K98k.

The second variant of the K98k was a rifle with a grenade launcher, introduced in 1942. At the muzzle of such a weapon was mounted a device for firing rifle grenades. In each infantry team of the Wehrmacht there was one soldier equipped with a rifle with a grenade launcher and a supply of appropriate ammunition.

The grenade launcher has a caliber of 30 mm, the guide part of the bore is provided with eight grooves and its total weight is 0.78 kg. The grenade launcher could fire various types of fragmentation and anti-tank (cumulative) grenades up to a distance of 250 meters.

Special sights, mounted on the left side of the weapon under the ammunition chamber, were used to aim the grenade launcher.

Construction

The Mauser K98k rifle is a repeating weapon with a revolving retractable breech. The ammunition is stored in a two-row, fixed ammunition box, situated in front of the trigger guard. The box is filled from above using a charging tape.

The main parts of the rifle are: Barrel with sights, breech case, breech, ammunition box and stock.

The barrel with a length of 600 mm is equipped with four clockwise grooves, with a constant pitch of 240 mm. The rear part of the bore mainly passes into the charge chamber.

The base of the visor is soldered on the back of the barrel; in the front part of the barrel is soldered to the base of the fly. The barrel has a thread in the rear part, which is screwed into the breech case.

The breech case connects all the basic parts of the weapon into one unit. In the front part of the breech housing, in the sleeve of the housing, there is a thread into which the barrel is screwed; in the remaining length of the housing there is a bore in which the bolt moves. Longitudinal grooves are milled in the side walls of the bore, which guide the locking teeth and thus the closure during the longitudinal movement of the closure. The rear part of the closure housing is closed from above and forms a so-called housing bridge; in the front part of the bridge, cutouts are milled for attaching the charging tape.

On the left side of the rear part of the bolt housing, a spring-loaded bolt holder is attached with a screw. The protrusion of the bolt holder engages in a side groove in the housing, thus forming the rear stop of the bolt and at the same time preventing it from being unintentionally pulled out.

The closure consists of a bolt, extractor, extractor ring, firing pin, drum spring, firing pin nut, closures, pin spring closures and fuses.

Three locking teeth (two at the front and one at the rear) are milled in the bolt, which fit into the respective recesses in the bolt housing; the downwardly curved handle of the breech also extends from the breech.On the right side of the bolt is a rotary extractor.

A drum spring is threaded on the firing pin and a firing pin nut is fitted to its rear end with a bayonet connection.

The firing pin nut has a bar at the bottom, the front end of which is chamfered. This chamfer corresponds in its angle to the helical surface in the notch of the bolt; when the bolt is turned to the left, the firing pin nut is pushed backwards and thus the drum spring is tensioned. At the bottom of the firing pin nut bar, there are two teeth that are used to catch the trigger lever tooth.

The closure, which is screwed to the bolt, connects the individual parts of the bolt. A fuse and a spring-loaded closure pin are housed in the cap. The pin ensures the correct position of the closure relative to the bolt and also prevents rotation of the unlocked bolt.

The aileron safety device is placed in the closure with its pin and has three positions - unlocked on the left, locked upwards and in the position of the safety wing aileron on the right it is secured and in addition blocked the movement of the closure.

A trigger device is also located in the closure housing, which consists of a trigger with a pin, a trigger spring and a trigger lever with a pin. The spring pushes the trigger lever up, where it catches the firing pin nut with its tooth. Pressing the trigger lowers the rear of the trigger lever, the tooth disengages, and the firing pin nut is released. When the trigger pressure is released, the trigger lever returns to its original position.

The cartridge box is bolted to the breech housing with two screws from below. The box is formed by the body of the box, which forms one unit with the trigger guard, bottom, feed spring and feeder. The bottom of the box is attached to the body with a spring pin. A folded flat spring is inserted in the bottom of the box, which pushes the cartridge feeder upwards. The cartridges are stored in the box in a checkerboard pattern in two rows.

The stock and forearm are made of solid walnut wood or, more often, of laminated beech veneer; exceptionally, the stock was made of another type of solid wood. The breech case is attached to the stock by means of two through screws, which at the same time connect the case with the cartridge case. In front of the breech case, a barrel is placed in the stock along its entire length, which barrel is attached to the stock by means of two barrel sleeves; a bayonet catch protrudes forward from the front main sleeve. The recoil of the shot is transmitted to the stock by means of a square pin bed located under the ammunition chamber.

In the head of the stock there is an opening for threading the carrying belt and behind it there is a bed for disassembling the breech. The rear part of the stock head is protected against damage by a steel shoe.

Technical data

Caliber - 7.9 mm

Hub - 7,9 mm mod. 98 (today's designation 8x57JS)

Length - 1110 mm

Length with bayonet - 1340 mm

Length with grenade launcher - 1265 mm

Empty weight - with walnut stock - 3.7 kg

Empty weight - with beech stock - 3.9 kg

Empty weight - with laminated stock - 4.1 to 4.2 kg

Empty weight - with plastic stock - 4.06 kg

Weight of loaded weapon with bayonet - 4.33 kg (with walnut stock)

Weight with grenade launcher and sight - 5.35 kg (with walnut stock)

Barrel length - 600 mm

Number of grooves in the barrel - 4

Bore pitch - 240 mm

Sense of ascent - true

Depth of grooves - 0.12 mm

Groove width - 4.40 mm

Muzzle velocity - 860 m/s

Ammunition box capacity - 5 rounds

Visor range - 100 to 2000 m

Handling K98k rifle:

Hold the weapon under the ammunition box with your left hand. Grasp the handle of the breech with your right hand, turn it to the left upwards and pull the breech back. On the right, grab the charging strap with the hubs and insert it into the cutout in the bridge of the breech case. Then we support the bottom of the cartridge case from below with four fingers of the right hand, place the thumb on the highest cartridge and push the cartridges into the box with the pressure of the thumb. With the right hand, grasp the handle of the breech, move the breech forward, thus inserting the highest charge into the chamber. After reaching the end to the front position and turn the crank to the right. The charging strap falls off when the shutter moves forward.

After the shot, we reload the weapon by turning the handle to the left up, pulling the breech back to the stop, which pulls it out of the chamber and throws the empty cartridge case. Then move the bolt forward as far as it will go and lock it by turning the handle to the right. The weapon is ready for another shot.

Production

In total, about 14 million K98k rifles were produced. The last series of K98k rifles was produced in Germany between August 1945 and June 1946 for the needs of the French army. The production of K98k for the needs of the Czechoslovak Army after the war also took place in the Brno Armory.

Production in individual plants:

Races in Germany:

5,154,000 pcs - Mauser-Werke A.G., Oberndorf am Neckar

1,089,000 pcs - Mauser-Werke A.G., Berlin-Borsigwalde

1 981 000 pcs - J. P. Sauer -und Sohn Gewehrfabrik, Suhl

654,000 pcs - Erfurter Maschinenfabrik Berthold Geipel GmbH (ERMA), Erfurt

878 000 pcs - Berlin-Lübecker Maschinenfabrik Bernhard Berghaus, Lübeck

131,000 pcs - Berlin-Suhler-Waffen-u. Fahrzeugwerke, Suhl

1,216,000 pcs - Gustloff Werke, Weimar

Plants in occupied countries:

965,000 pcs - Steyr-Daimler-Puch A.G., Steyr

1,030,000 pcs - Waffenwerke Brünn A.G. (Zbrojovka Brno a.s.), Brno plant

942,000 pcs - Waffenwerke Brünn A.G., plant Povážská Bystrica

Marking

The designation of the K98k rifles consisted of several elements: type designation, serial number, manufacturer's designation, year of manufacture, test marks and acceptance marks.

The type designation was located on the left side of the breech housing and had the form " Mod. 98" (without the suffix "k"). Before 1936, however, only weapons made at Mauser's parent plant in Oberndorf were marked in this way. This marking was made in ordinary block letters, for weapons manufactured by Sauer and Erma then Schwabach.

Some K98k rifles, modified from the original G98, bore the original designation " Gew. 98 ". Most of these weapons were used by the Nazi party organization SS.

The serial number was located on the left side of the breech case sleeve, on the underside of the breech handle, and on the barrel. The serial number initially consisted of three digits, later four digits and a one-letter suffix. On some parts, the serial number was repeated in abbreviated form.

The manufacturer's code first consisted of a capital letter "S" followed by a slash followed by a two- to three-digit number identifying the manufacturer - for example, Mauser-Werke in Oberndorf had the code "S/42".

In 1938, the letter "S" with a slash was deleted from the code and the manufacturer was identified only by the numerical code, which remained.

In 1940, a completely new manufacturer's code system was introduced, consisting of two to three lower case letters - for example, Mauser-Werke in Oberndorf had the code "byf".

Exceptions to this marking system were the products of Berlin-Suhler-Waffen- und Fahrzeugwerke from Suhl, which were marked with the stylized letters " BSW ", or the abbreviation of the company name.

The year of manufacture designation has also changed over time. The first two years of production were K98k rifles marked with a one-letter code - weapons made in 1934 bore the code "K", in 1935 the code "G". The code of the year followed immediately after the manufacturer's designation, but sometimes it was separated from it by a slash, exceptionally by a period. The letter was usually in capital letters, but sometimes in small print. Example: a rifle made by Mauser-Werke in Oberndorf in 1934 was marked " S/42K", a rifle made by JP Sauer in Suhl in 1935 it bore the designation " S/147/G", the weapon made in Erfurter Maschinenfabrik in 1935 was marked " S/27.g ".

Since 1936, the year of manufacture of the weapon was marked with an integer year, which was located in the rear of the upper surface of the sleeve of the breech.

From the end of 1940, the year of production was marked only by stating the last two digits of the year of production.In 1940, however, only weapons made in Steyr, Austria were marked in this way, other manufacturers did not switch to this method until the beginning of 1941. An exception to this system were weapons made by the Brno Armory, which was now called Waffenwerke Brünn. A.-G.[/I] Her weapons were marked until the end of 1944 for the whole year of production.

In addition to the manufacturer's name, there was also a military acceptance mark on the right of the breech case. In each production plant, there was a group of officers of the Waffenamt (armaments office), which was responsible for taking over weapons for the army. The commanding officer of each group was assigned a set of verification mark stamps ( Abnehmestempel) with an assigned number. There were more stamps, of course, but all members of the group used the same number. After the acceptance inspection, it was marked on the weapon with the embossing of an eagle and the assigned group number, which was sometimes preceded by the abbreviation " WaA". Interestingly, the group number was not tied to the production plant, but to the person of the group's commanding officer - if he was transferred to another plant, the numbers traveled with him. The commander, coming to the vacated position, brought his own number with him, although the group had not changed otherwise.

Very often it is possible to find on the individual components of K98k rifles (and other weapons) several codes of manufacturers or groups of the Waffenamt, different from the markings on the sleeve of the breech. These components were manufactured by various subcontractors and were only assembled by the final weapon supplier.

Manufacturer code K98k:

Until 1938:

BSW - Berlin-Suhler-Waffen-u. Fahrzeugwerke, Suhl

S/27 - Erfurter Maschinenfabrik GmbH, Erfurt

S/42 - Mauser-Werke A.G., Oberndorf

S/147 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl

S/237 - Berlin-Lübecker Maschinenfabrik, Lübeck

S/243 - Mauser-Werke A.G., Berlin-Borsigwalde

From 1938 to 1940:

BSW - Berlin-Suhler-Waffen-u. Fahrzeugwerke, Suhl

27 - Erfurter Maschinenfabrik GmbH, Erfurt

42 - Mauser-Werke A.G., Oberndorf

47 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl

147 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl

237 - Berlin-Lübecker Maschinenfabrik, Lübeck

243 - Mauser-Werke A.G., Berlin-Borsigwalde

337 - Berlin-Suhler-Waffen-u. Fahrzeugwerke, Suhl

660 - Steyr-Daimler-Puch A.G., Steyr

In the years 1940 - 1945:

ar - Mauser-Werke A.G., Berlin-Borsigwalde

ax - Erfurter Maschinenfabrik GmbH, Erfurt

ayf - Erfurter Maschinenfabrik GmbH, Erfurt

bcd - Gustloff Werke, Weimar

bnz - Steyr-Daimler-Puch A.G., Steyr

byf - Mauser-Werke A.G., Oberndorf

ce - J. P. Sauer -und Sohn Gewehrfabrik, Suhl

dot - Waffenwerke Brünn A.G. (Zbrojovka Brno a.s.), Brno plant

dou - Waffenwerke Brünn A.G. (Zbrojovka Brno a.s.), Povážská Bystrica plant

duv - Berlin-Lübecker Maschinenfabrik, Lübeck

swp - Waffenwerke Brünn A.G., Brno plant (only in 1945)

svw - Mauser-Werke A.G., Oberndorf (only in 1945)

svw MB - Mauser-Werke A.G., Oberndorf (weapons made in 1945 for the occupation administration)

Waffenamt acceptance marks:

1 - Gustloff-Werke, Weimar (1940-1941 and 1944-1945)

2 - Mauser Werke A.G., Oberndorf

4 - Berlin-Suhler-Waffen-u. Fahrzeugwerke, Suhl (1937-1939)

26 - Berlin-Lübecker Maschinenfabrik, Lübeck (1936-1938)

26 - Gustloff-Werke, Weimar (1942-1943)

26 - Mauser Werke A.G., Berlin-Borsigwalde (1939-1944)

42 - Mauser Werke A.G., Oberndorf

46 - Berlin-Suhler-Waffen-u. Vehicle works, Suhl (1939)

63 - Mauser Werke A.G., Oberndorf (1936-1939)

63 - Waffenwerke Brünn A.G., Brno plant (1943-1944)

63 - Waffenwerke Brünn A.G., plant Povážská Bystrica (1945)

74 - Mauser Werke A.G., Oberndorf (1934)

77 - Erfurter Maschinenfabrik GmbH, Erfurt (1937-1938)

77 - Steyr-Daimler-Puch A.G., Steyr (1942-1944)

80 - Waffenwerke Brünn A.G., Brno plant (1942)

80 - Waffenwerke Brünn A.G., plant Povážská Bystrica (1943-1945)

91 - Mauser Werke A.G., Oberndorf (1934)

114 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl (1934-1935)

116 - J. P.Sauer -und Sohn Gewehrfabrik, Suhl (1934-1936)

132 - Erfurter Maschinenfabrik GmbH, Erfurt (1935)

135 - Mauser Werke A.G., Oberndorf (1942-1945)

149 - Berlin-Lübecker Maschinenfabrik, Lübeck (1938)

165 - Mauser Werke A.G., Oberndorf (1935)

167 - Mauser Werke A.G., Oberndorf (1935)

211 - Mauser Werke A.G., Berlin-Borsigwalde (1935-1936)

214 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl (1936-1940)

214 - Berlin-Lübecker Maschinenfabrik, Lübeck (1941-1941)

280 - Erfurter Maschinenfabrik GmbH, Erfurt (1936-1940)

280 - Mauser Werke A.G., Berlin-Borsigwalde (1937-1938)

280 - Berlin-Lübecker Maschinenfabrik, Lübeck (1938)

280 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl (1942-1944)

280 - Erfurter Maschinenfabrik GmbH, Erfurt (1940-1941)

359 - J. P. Sauer -und Sohn Gewehrfabrik, Suhl (1936-1943)

359 - Erfurter Maschinenfabrik GmbH, Erfurt (1941)

411 - Erfurter Maschinenfabrik GmbH, Erfurt (1936)

613 - Mauser Werke A.G., Berlin-Borsigwalde (1941)

623 - Steyr-Daimler-Puch A.G., Steyr (1939-1945)

655 - Mauser Werke A.G., Oberndorf (1939-1941)

K98k in Czechoslovakia

The first K98k rifles appeared on the territory of the former Czechoslovakia in the second half of the 1930s under well-known tragic circumstances - they found themselves in the hands of terrorists from the Sudeten German paramilitary organization Freikorps. Members of the Freikorps, willingly supplied and ideologically incited by Hitler's Germany, led a terrorist campaign on the Czech border, and the main targets of their insidious attacks were mainly symbols of Czechoslovak statehood - soldiers, gendarmes, members of the Financial Guard and civil servants.

The second wave of K98k rifles "came" to our territory in even more tragic circumstances - along with the occupying forces of the Wehrmacht in March 1939, which settled in our country for the next six years.

During the war in the German Wehrmacht, the need (and consumption) of all kinds of weapons constantly increased. At the beginning of 1942, the production of K98k rifles was terminated at the Erfurt plant Erma, which fully switched to the production of a submachine gun MP-40, and it was necessary to quickly find new production capacity. These were found in the former subsidiary of Brno's Zbrojovka in Povážská Bystrica, Slovakia, which had experience from the pre-war period with the production of Czechoslovak army rifles vz.24. The adoption of production took place relatively quickly, and in 1942 95,000 K98k rifles were produced. A total of 942 thousand of these weapons were produced in Povážská Bystrica.

In 1943, the production of K98k rifles began in the main Brno plant Zbrojovka, as a replacement for the termination of production in the Berlin-Lübecker Maschinenfabrik, which has since focused on the production of self-loading rifles G43. In the first year of production, 1943, 220,000 K98k rifles left the Brno plant and a total of 1.03 million weapons by the end of the war.

After the Second World War, an extensive "legacy" of the German occupiers remained in our territory, which also included a considerable number of K98k rifles. Due to the lack of other weapons and the need for uniform armament of the renewed army, K98k rifles were included in the armament of the Czechoslovak Army under the designation vz.98N. Other German weapons classified in this way were, for example, assault rifles StG44, machine guns MG34 or pistole P38. In addition, an undetected number of prey rifles were delivered from the Soviet Union. These weapons were called "Stalingrad rifles" in our army because they were allegedly captured during the Battle of Stalingrad.

What is more important, the production of rifles vz.98N for Czechoslovakia. the army in Brno's Zbrojovka took place for several years after the end of the war. In the Czechoslovak armament. army rifles vz.98N lasted until the early 50s, when they were gradually replaced submachine guns vz.23/24/25/26 a samonabíjecími puškami vz.52.

Part of the loot weapons was sold to Israel in 1948, the remaining vz.98N were sold abroad after being expelled from the army.

Reklama

Caliber: 7.92 mm

Magazine: integrated cartridge box

Capacity: 5 rounds

Magazine retention: none

Type of weapon: repeating rifle with sliding cylinder breech

Firing mode: single shot

Breech lock: two locking teeth

Overall length: 1120 mm

Barrel length: 610 mm

Weight: 3,8 kg

Sights: sliding sight

Manual safety: at the rear of the breech

Stock: wood

Modified by moderator (Piti) on 10/20/2005

Magazine: integrated cartridge box

Capacity: 5 rounds

Magazine retention: none

Type of weapon: repeating rifle with sliding cylinder breech

Firing mode: single shot

Breech lock: two locking teeth

Overall length: 1120 mm

Barrel length: 610 mm

Weight: 3,8 kg

Sights: sliding sight

Manual safety: at the rear of the breech

Stock: wood

Modified by moderator (Piti) on 10/20/2005

Reklama

Between 1940 and 1945:

ar - Mauser-Werke A.G., Berlin-Borsigwalde

ax - Erfurter Maschinenfabrik GmbH, Erfurt

ayf - Erfurter Maschinenfabrik GmbH, Erfurt

bcd - Gustloff Werke, Weimar

bnz - Steyr-Daimler-Puch A.G., Steyr

byf - Mauser-Werke A.G., Oberndorf

ce - J. P. Sauer -und Sohn Gewehrfabrik, Suhl

dou - Waffenwerke Brünn A.G. (Zbrojovka Brno a.s.), Brno plant

dot - Waffenwerke Brünn A.G. (Zbrojovka Brno a.s.), Povážská Bystrica plant

duv - Berlin-Lübecker Maschinenfabrik, Lübeck

swp - Waffenwerke Brünn A.G., Brno plant (only in 1945)

svw - Mauser-Werke A.G., Oberndorf (only in 1945)

svw MB - Mauser-Werke A.G., Oberndorf (weapons produced in 1945 for the occupation administration)

ar - Mauser-Werke A.G., Berlin-Borsigwalde

ax - Erfurter Maschinenfabrik GmbH, Erfurt

ayf - Erfurter Maschinenfabrik GmbH, Erfurt

bcd - Gustloff Werke, Weimar

bnz - Steyr-Daimler-Puch A.G., Steyr

byf - Mauser-Werke A.G., Oberndorf

ce - J. P. Sauer -und Sohn Gewehrfabrik, Suhl

dou - Waffenwerke Brünn A.G. (Zbrojovka Brno a.s.), Brno plant

dot - Waffenwerke Brünn A.G. (Zbrojovka Brno a.s.), Povážská Bystrica plant

duv - Berlin-Lübecker Maschinenfabrik, Lübeck

swp - Waffenwerke Brünn A.G., Brno plant (only in 1945)

svw - Mauser-Werke A.G., Oberndorf (only in 1945)

svw MB - Mauser-Werke A.G., Oberndorf (weapons produced in 1945 for the occupation administration)

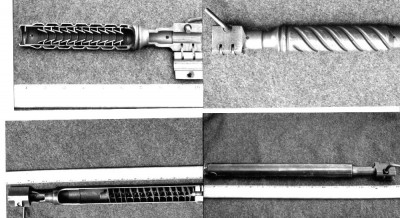

I attach photos of my shock absorbers on the kar98, I found that there were two kinds. One, how is the fotu is a helix around the ( very vzacnejši type ) and then, without a helix. Everything is original, only the loop is done the new. Unfortunately, it is kopaný but the damage on it is I would rather be evaluated as from an explosion, because of the similar has also a rifle, with which he was found, and it is obviously from the up of fragments..

Just for the complete rifle which is the photographing was made in the year 1937 in Oberndorf ( code S/42 )..

Just for the complete rifle which is the photographing was made in the year 1937 in Oberndorf ( code S/42 )..

According to photos goes on the shock absorber called the HUB L25 (Arado system), subsonická ammunition, of course, existed, and, moreover, is not a prerequisite for the use of the silencer. If it is not used subsonická ammo is silenced muted just the noise of the shot (i.e. the expansion of the gases behind the shot) but it is not (but the silencer is never) attenuated sonický bang flying missiles. Shock absorber in the case of using normal ammo will remove the sound of the shot which is to identify the location of the shooter to the most important and private sonický bang will remain, but the latter is much more difficult to be localized.

For clarity, how this thing looked inside, I attach a photo. The type of shock (here it should be L 25) was imprinted on edison, underpinning it to the barrel, similar was done for a variety of other weapons including kořistních, signs then, of course, vary.

the source of the photos: www.ww2incolor.com.

For clarity, how this thing looked inside, I attach a photo. The type of shock (here it should be L 25) was imprinted on edison, underpinning it to the barrel, similar was done for a variety of other weapons including kořistních, signs then, of course, vary.

the source of the photos: www.ww2incolor.com.

Diskuse

Citace - G41M :

Servus chlapi.

Who knows what the rivet in the stock was used for?

To parse the breech.

You secure the bolt and remove it from the bolt carrier. You unscrew the bolt from the bolt carrier with the firing pin preloaded with a percussion spring. Then you seat the firing pin in that bed in the stock, push the bolt down against the compression of the percussion spring, turn the firing pin nut 90° and remove it. Then you just release the pressure on the spring and the firing pin and firing pin drops into your hand. Reverse the order.

Join us

We believe that there are people with different interests and experiences who could contribute their knowledge and ideas. If you love military history and have experience in historical research, writing articles, editing text, moderating, creating images, graphics or videos, or simply have a desire to contribute to our unique system, you can join us and help us create content that will be interesting and beneficial to other readers.

Find out more